FIRELORDS CNC Extinguishing Systems (CO2 IHP – Indirect High Pressure)

It is designed to detect and extinguish fires that may occur in CNC Machines locally.

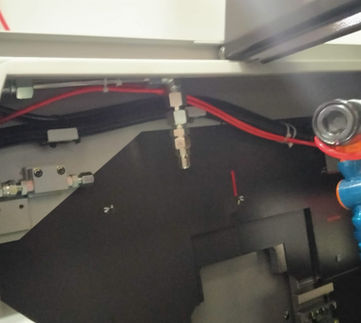

Indirect systems detect fire with a heat and flame sensitive detection line; They are compact extinguishing systems that provide extinguishing from the piping mechanism by activating the system.

Hydraulic calculations are made and the hole diameters are predetermined in CNC machines with nozzle type and piping installation. The sensing line, which is assembled in CNC Machines, explodes from one or more places due to heat increase or flame contact. Relief of the pressure inside the sensing activates the system valve, allowing the carbon dioxide gas to discharge into the CNC machine through the piping system.

Carbon dioxide gas:

● It is high pressure by nature,

● Provides instant cooling with the effect of dry ice and thermal shock,

● It is 1.53 times heavier than air and cuts off the flame source by suffocating oxygen.

Optional products available:

Gas Released Switch:

It is mounted on the piping system that allows the carbon dioxide gas to be discharged into the cabin, and provides contact during gas passage from the installation. Contact can be used for all commands desired to be performed during gas discharge.

Indirect System Capacities:

● 2.0 kg. systems up to a maximum of 1.3 cubic meters,

● 4.0 kg. systems up to a maximum of 2.6 cubic meters,

● 6.0 kg. systems up to a maximum of 3.9 cubic meters,

Hydraulic and design calculations of the systems were made with a design concentration of 41% to provide extinguishing with CO2 extinguishing agent in the CNC benches in the interior spaces.

For CNC machines with larger internal volume, hydraulic calculations and designs up to 10.0 and 15.0 kg have been completed and extinguishing is provided with the required system capacities.